HotTapping-Machines.com

Free Tech Support on All Machines Sold For Life.

- Hot Tapping Machines

Hot Tapping Machines

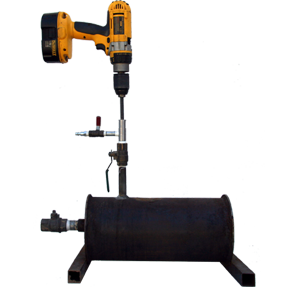

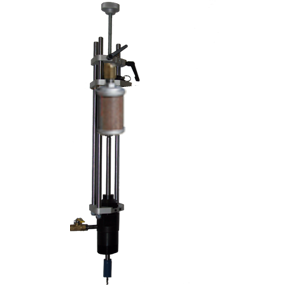

- 1/8"-3/4" Micro Hot Tapping Machine

This tapping machine will perform 1/8"-3/4" hot taps. This machine uses solid drill bits for performing the hot tap under pressure for branch connections of up to 150 psi @ 250 D. F maximum. Total: $595.00 + Shipping

More Information . . .

Call us today! 951-223-5574

or email us

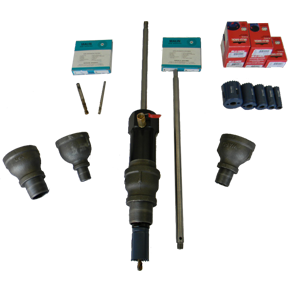

- 1/2"-1 1/4" Mini Hot Tapping Machine

This tapping machine will perform 1/2"-1 1/4" hot taps. This machine uses solid drill bits for performing the hot tap under pressure for branch connections of up to 175 psi @ 250 D. F maximum. Total: $955.00 + Shipping

More Information . . .

Call us today! 951-223-5574

or email us

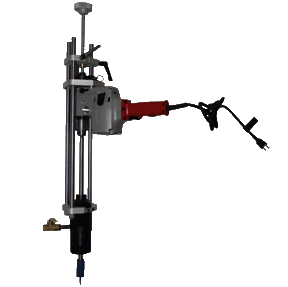

- 3/4"-2" Hot Tap Machine

This hottap machine will perform 3/4"-2" hot taps. This package can be upgraded at any time to perform up to 6" hot taps. WT machine is rated for: 150 psi @ 250 Deg F. Total: $1,195.00 + Shipping

More Information . . .

Call us today! 951-223-5574

or email us

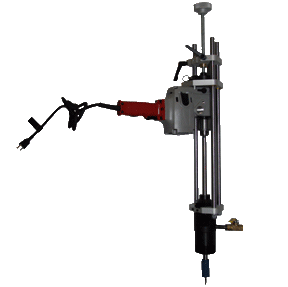

- 1/2"-2" Hot Tapping Machine

This tapping machine will perform 1/2"-2" hot taps. This package can be upgraded at any time to perform up to 6" hot taps. WT machine is rated for: 300 psi @ 100 deg F 250 Deg F @ 200 psi available high temp packing to 495 deg @ 200 psi.

More Information . . .

Call us today! 951-223-5574

or email us

- 1/2"-4" Hot Tapping Machine

This tapping machine will perform 1/2"-4" hot taps. WT machine is rated for: 300 psi @ 100 deg F 250 Deg F @ 200 psi available high temp packing to 495 deg @ 200 psi.

More Information . . .

Call us today! 951-223-5574

or email us

- 1/2"-4" Air Drive Hot Tapping Machine

This tapping machine will perform 1/2"-4, and is equipped with a very strong Air motor. This machine is designed for the NO SPARK applications on gas hot taps. This package can be upgraded at any time to perform up to 4"

More Information . . .

Call us today! 951-223-5574

or email us

- 1/8"-3/4" Micro Hot Tapping Machine

- Hot Tapping Machines

Hot Tapping Machines

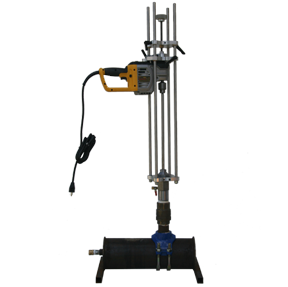

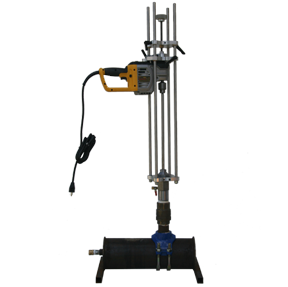

- 1/2"-4" Quad Rail Hot Tapping Machine

Design eliminates any twisting or flexing under extreme hot taps. Allows the user to install the drive motor 4 different directions depending on the space or location of the hot tap! Different length Quad rails give the machine the ability to perform hot taps in tight locations.

More Information . . .

Call us today! 951-223-5574

or email us

- 1/2"-6" Quad Rail Hot Tapping Machine

Design eliminates any twisting or flexing under extreme hot taps. Allows the user to install the drive motor 4 different directions depending on the space or location of the hot tap! Different length Quad rails give the machine the ability to perform hot taps in tight locations.

More Information . . .

Call us today! 951-223-5574

or email us

- 1/2"-4" High Pressure Hot Tap Machine

Severe Duty 1/2"-4" Tapping machine 18" of travel, This machine is time tested and heavy duty! Can be used on Gas,water,steam and many other severe duty applications! also compatible for line stopping! Air and electric drives available. This machine comes with Packing wrench and D clips for installing Pilot drill/cutter mandrel. Extra High temp packing and parts in stock! 1450 psi@ 100 deg F 700 deg. F @ 700 PSI

More Information . . .

Call us today! 951-223-5574

or email us

- 1/2"-8" High Pressure Hot Tap Machine

Severe Duty 1/2"-8" Tapping machine. 28" of travel., This machine is time tested and heavy duty! Can be used on Gas,water,steam and many other severe duty applications! also compatible for line stopping! Air and electric drives available. This machine comes with Packing wrench and D clips for installing Pilot drill/cutter mandrel. Extra High temp packing and parts in stock! 1450 psi@ 100 deg F 700 deg. F @ 700 PSI

More Information . . .

Call us today! 951-223-5574

or email us

- 3"-12" Quad Rail Hot Tapping Machine

3in-12in Quad Rail Tapping Machine This machine performs 3"-12" under pressure taps Hydraulic, Air or Electric drives available Gear driven for the ultimate in performance and reliability

More Information . . .

Call us today! 951-223-5574

or email us

- 3"-16" Quad Rail Hot Tapping Machine

3in-16in Quad Rail Tapping Machine Package This machine performs 3"-16" under pressure taps 40" of overall travel Hydraulic or electric drive Gear driven for the ultimate in performance and reliability

More Information . . .

Call us today! 951-223-5574

or email us

- 12"-24" Quad Rail Hot Tapping Machine

12in-24in Quad Rail Tapping Machine This machine performs 12"-24" under pressure taps Use Hydraulic or Electric drives on the same machine depending on what you need.

More Information . . .

Call us today! 951-223-5574

or email us

- 1/2"-4" Quad Rail Hot Tapping Machine

- Hydro Power Packs

Hydraulic Power Packs and Units

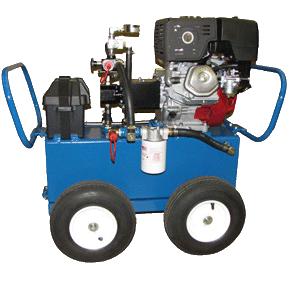

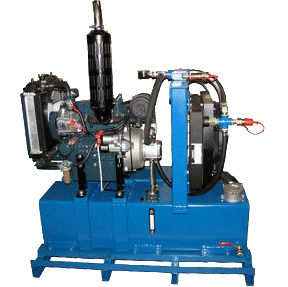

- 13 H. 8 GPM. 2000 PSI. Gas Hydro Pack

These items are Installed on this line of Power Units. This hydraulic power pack is the perfect unit for our line of smaller 3"-12" hydraulic tapping machines Add a wheel package and make it a portable unit!

More Information . . .

Call us today! 951-223-5574

or email us

- 24 H. 15 GPM. 2000 PSI. Gas Hydro Pack

24 H.P Honda heavy duty series 15 GPM @ 2000 psi. This model power pack is used for our medium sized hot tapping machines 4"-16". Many different GPM and Pressure ratings available, please call and we can customize any power pack to fit your needs.

More Information . . .

Call us today! 951-223-5574

or email us

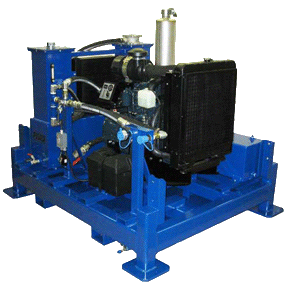

- 25 H. 15 GPM. 2000 PSI. Diesel Hydro Pack

25 Horse Power Diesel Hydraulic Power Packs 25 HP Kubota Liquid Cooled Diesel Engine E.P.A TIER 111 Exhaust Emission Compliant 4-Stroke Diesel Power Pack Direct Fuel Injection 12 Gallon Fuel Tank

More Information . . .

Call us today! 951-223-5574

or email us

- 35 H. 25 GPM. 1500 PSI. Diesel Hydro Pack

35 Horse Power Diesel Hydraulic Power Packs 35 HP Kubota Liquid Cooled Diesel E.P.A TIER 111 Exhaust Emmision Compliant Liquid-Cooled 4-Stroke Diesel Power Pack Direct Fuel Injection 25 Gallon Fuel Tank

More Information . . .

Call us today! 951-223-5574

or email us

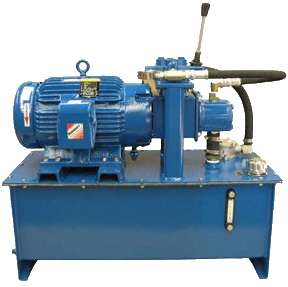

- 10 H. 2000 PSI. Electric Hydro Pack

8 GPM @ 2000 psi. This hydraulic power pack is perfect for indoor hot tapping or other applications. Pair this up with our 3"-12" hydraulic tapping machine and tap anywhere indoors!

More Information . . .

Call us today! 951-223-5574

or email us

- 25 H. 2000 PSI. Electric Hydro Pack

28 GPM @ 2000 PSI This unit is designed for our larger custom line of tapping machines for indooe use. Can be made with a skid type of mounting paltform or a custom cage for crane lifting. Please call for a custom quote and design spec

More Information . . .

Call us today! 951-223-5574

or email us

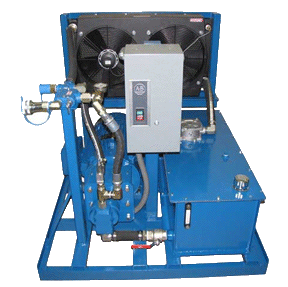

- 40 H. 2000 PSI. Electric Hydro Pack

28 GPM @ 2000 PSI This unit is designed for our larger custom line of tapping machines for indooe use. Can be made with a skid type of mounting paltform or a custom cage for crane lifting. Please call for a custom quote and design spec.

More Information . . .

Call us today! 951-223-5574

or email us

- 13 H. 8 GPM. 2000 PSI. Gas Hydro Pack

- Tapping Saddles

Tapping Saddles and Services Saddles

- Copper Pipe Saddles/Sleeves

These saddles/sleeves are specifically designed for use on copper mains. Our saddles can be used on domestic water, heating hot water, Air, natural gas, glycol and sewage mains. All saddle have a stainless steel IP male thread for easy installation of you full port ball valve. Please call with any questions and we will gladly help you pick the correct saddle for your application.

More Information . . .

Call us today! 951-223-5574

or email us

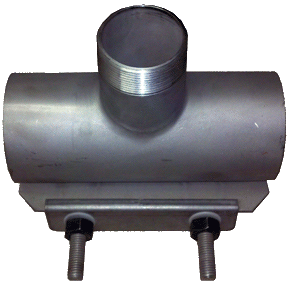

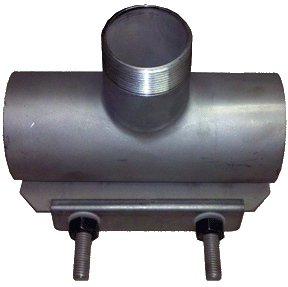

- PVC/Steel Saddles/Sleeves

These saddles/sleeves are designed specifically for steel and pvc mains All saddles have a stainless steel IP male thread for easy installation of you full port ball valve. Please specify main size and outlet size when ordering. If you have any questions about these tapping saddles please call and we can help you pick the correct saddle for your needs.

More Information . . .

Call us today! 951-223-5574

or email us

- Copper Pipe Saddles/Sleeves

- Tapping Fittings

Pipe Fittings

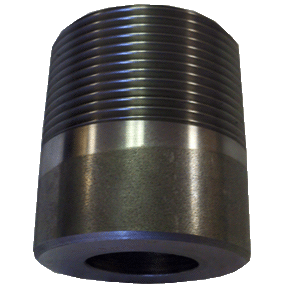

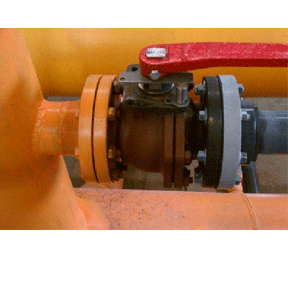

- Qualitec Fittings

3/4"-4" linestop fittings. Each fitting comes with completion plug and cap 300 psi max rating

More Information . . .

Call us today! 951-223-5574

or email us

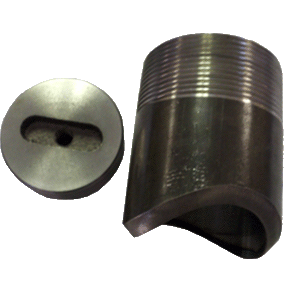

- Therm-o-Well Fittings

1/2" & 3/4" thermowell fittings are designed to be welded onto steel mains. Once the fitting is welded in place you can install a ball valve or gate vale on the outside of the fitting. Once this is performed you can install our WT-3/4-2" Tapping machine and solid bit to perform the hottap. Once the hot tap is performed you close the temporary ball valve or gate valve and remove the WT-3/4-2" Tapping machine.

More Information . . .

Call us today! 951-223-5574

or email us

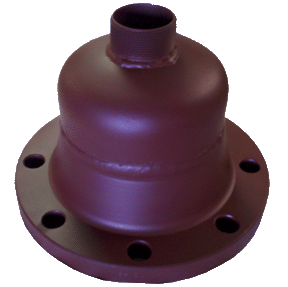

- Full Wrap Fittings

Full Wrap hot tap fittings are designed to be welded onto CMLC pipelines for structural support on the thin walled steel pipe. we start off with our standard ANSI 150 lb flanged hot tap fitting and design a wrapper to be installed and welded to give support during and after the hot tap.

More Information . . .

Call us today! 951-223-5574

or email us

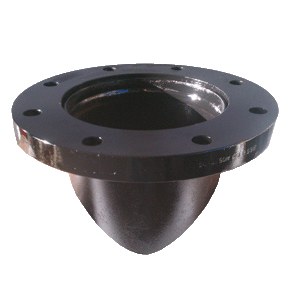

- Contoured Hottap Fittings

Contoured Hottap We build contoured Weld fittings designed for ANSI 150 lb and ANSI 300 lb.flanged connections.

More Information . . .

Call us today! 951-223-5574

or email us

- Custom Weld Fittings

We offer Custom weld fittings for hot taps All of our weld nozzle fittings are designed and hand made to ensure proper installation with most fittings built off of ANSI 150 or ANSI 300 lb carbon steel flanges or stainless steel.

More Information . . .

Call us today! 951-223-5574

or email us

- Qualitec Fittings

- Tapping Holesaws

Holesaw Cutters

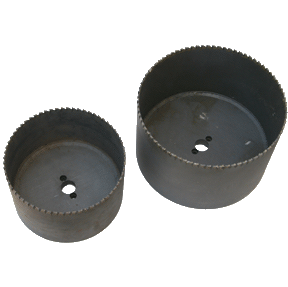

- High Speed Steel Hole Saw Cutters

High speed holesaws with a standard backing plate In addition We also Offer custom heavy duty carbide,diamond and tool steel holesaw cutters for most sizes 2 1/2"-60" and larger if needed.

More Information . . .

Call us today! 951-223-5574

or email us

- Carbide Hole Saw Cutters

Carbide holesaws with a standard backing plate In addition We also Offer custom heavy duty carbide,diamond and tool steel holesaw cutters for most sizes 2 1/2"-60" and larger if needed.

More Information . . .

Call us today! 951-223-5574

or email us

- Carbide Tipped Hole Saw Cutters

Carbide tipped Holesaws designed for use with our Line of Hot tapping machines Water works Tools line of double toothed hot tapping cutters can be made in any sizes and depths for line stopping to hot tapping. all of our cutters featured a brazed in carbide segments for long life and exceptional performance. All of our holesaws can be returned for repair and installation of new carbide cutting segments.

More Information . . .

Call us today! 951-223-5574

or email us

- Double Stack Hole Saw Cutters

Double Stack Holesaws come in either carbide tipped or high speed steel. These custom made holesaws have about 3.25" cutting depth with a heavy duty 3/16" thick steel backing plate. Please specify high speed steel or carbide tipped when ordering. if you do not see a size you need please call as we have the ability to build almost any size! Other options available are triple stack and custom depths.

More Information . . .

Call us today! 951-223-5574

or email us

- 3/4"-24" PVC Hole Saw Cutters

PVC carbide tipped cutters These cutters are specifically designed for cutting through Plastic or PVC pipe. Extra deep reliefs assure the chips are pushed out and do not bind up the cutter. Many different backing plate designs available for all types of tapping machines. Please call to get your custom quote today.

More Information . . .

Call us today! 951-223-5574

or email us

- Diamond Tipped Hole Saw Cutters

3/4"-24" PVC Plastic Deep Carbide Tipped Cutters These cutters are specifically designed for cutting through Plastic or PVC pipe. Extra deep reliefs assure the chips het pushe out and do not bind up the cutter.

More Information . . .

Call us today! 951-223-5574

or email us

- Tool Steel Hole Saw Cutters

Tool Steel Hole Saw Cutters Product images and information coming soon.

More Information . . .

Call us today! 951-223-5574

or email us

- Custom Carbide Tipped Hole Saw Cutters

These Cutsom Carbide tipped Holesaws can be customized to fin your type of hot tapping machines. Water Works Tools can take your blue prints and manufracture a double toothed hot tapping cutter made in any sizes and depths for line stopping to hot tapping. All of our cutters featured a brazed in carbide segments for long life and exceptional performance.

More Information . . .

Call us today! 951-223-5574

or email us

- High Speed Steel Hole Saw Cutters

- Pilot Drill Bits

Pilot Drill Bits for Coupon Retention

- 1/2"-6" Pilot Drill Bits

Our 1/2"-6" pilot drill bits are designed to catch the coupon or slug you have cut out of the pipe. Our pilot drill bits have dual holes in the flutes so you can run 2 sets of retention wire to ensure 100% positive retention of the coupon.

More Information . . .

Call us today! 951-223-5574

or email us

- 3"-24" Pilot Drill Shafts and Tips

Pilot Drills are specifically made for our line of larger hot tapping machines. 3"-24".The pilot drills are designed with the retention wires or keepers to catch the coupon. we designed the pilot drill with optional holes in the main body do so you can set the depth of the pilot in the cutter depending on the size of hot tap. If you need custom sizes for your machine please call and we'll be glad to help!

More Information . . .

Call us today! 951-223-5574

or email us

- 1/2"-6" Pilot Drill Bits

- Tapping Adapters

Tapping Adapters

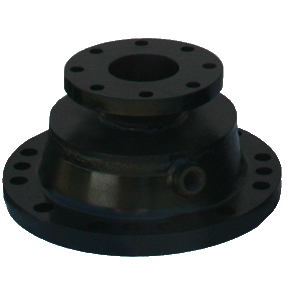

- 1/2"-6" Tapping Adapters

4" & 6" 150 lb. threaded flanged adaptors designed to be used with our WT-3/4"-6" line of tapping machines.

More Information . . .

Call us today! 951-223-5574

or email us

- 2"-6" High Pressure Tapping Adapters

High pressure machines 150 lb. 300 lb. 600 lb. These adaptors are designed for use with our Severe duty Tapping machines 1/2"-6" line of machines.

More Information . . .

Call us today! 951-223-5574

or email us

- 3"-24" MJ Bolt Tapping Adapters

ANSI 150 lb adaptor aso drilled for MJ bolt holes 3/4" testing/blow off port

More Information . . .

Call us today! 951-223-5574

or email us

- 1/2"-6" Tapping Adapters

-

Design by WaterWorksTools.com Add your website here

© All Copyrights Reserved by WaterWorksTools.com Privacy Policy